6.35×1.02×76.20 NE Series Water Jet Cutting Nozzle

Basic Info

Model No.: NE0635-102-762

Product Description

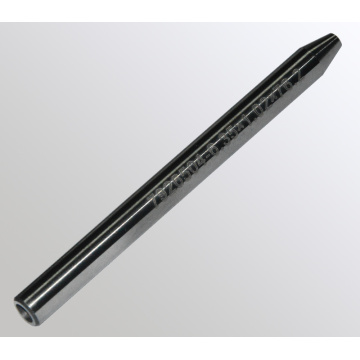

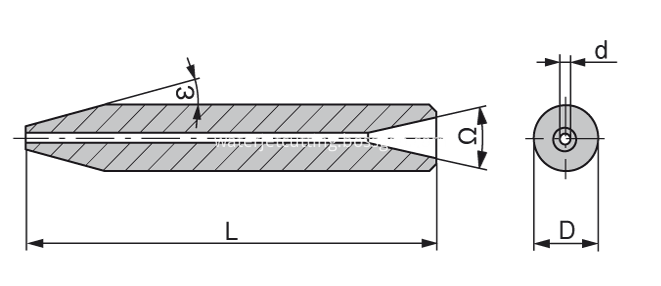

6.35 × 1.02 × 76.2 mm, indicating that the outer diameter of the sand mixing tube is 6.35 mm, the inner hole is 1.02 mm, and the length is 76.2 mm. The size of the inner hole of the sand tube is related to the cutting effect, so it is necessary to select a suitable inner hole to achieve the best cutting effect. For example, inner holes of 1.02 mm and 0.76 mm are most common in practical use. The outer diameter of the mixing tube is more random, depending on the matching cutting head made by the water cutting equipment factory. In order to achieve the purpose of monopoly, some waterjet cutting machine factories produce cutting heads with special specifications, which impose certain restrictions on the users when replacing the mixing tubes. At present, the more common sand mixing tubes have an outer diameter of 6.35 mm and 7.14 mm. In addition, the most common length of the mixing tube is 76.2 mm and 101.6 mm. Please choose a more suitable length of sand mixing tube. In addition to the three values of outer diameter, inner diameter and length, the inner cone angle of the sand mixing tube is also a non-negligible specification. The more appropriate the inner cone angle, the better the water sand mixture passes through the inner hole of the sand mixing tube. After a long-term practice, the 25 degree inner cone is the best.

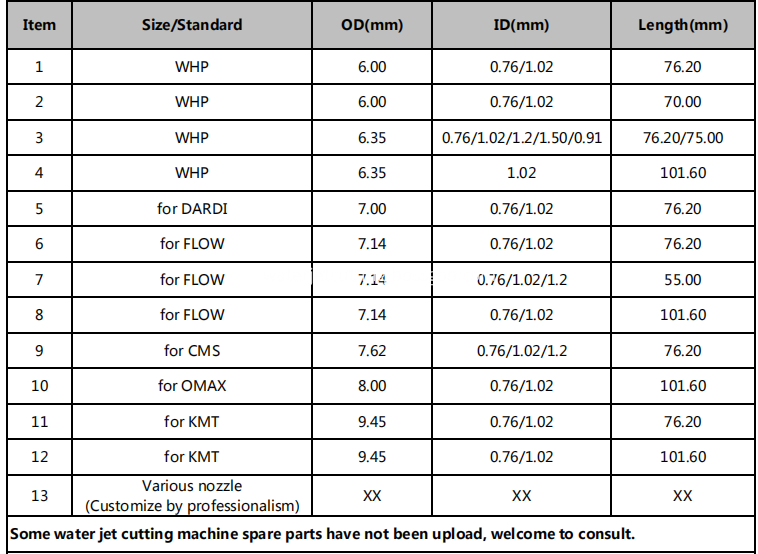

This water jet cutting nozzle is with 6.35×1.02×76.20 size. NE Series nozzle is economic waterjet nozzle. it is used for waterjet cutting. some customers also called it mixing tubes. this is AUSTRIA imported CERATIZIT nozzle. we have following size:

6.35×0.76×76.20

6.35×0.76×101.6

6.35×1.02×63.50

6.35×1.02×76.2

6.35×1.02×101.6

7.00×1.02×76.20

7.00×0.76×76.20

7.00×0.89×76.20

7.00×1.02×88.9

7.14×0.76×76.20

7.14×0.76×101.6

7.14×0.76×101.6R

7.14×0.89×76.2

7.14×0.84×76.2

7.14×1.02×76.2

7.14×1.02×88.9RNA

7.14×1.02×101.6

7.14×1.02×101.6R

7.62×0.84×76.2

There are many specifications for the mixing tube. It is mainly represented by three values of outer diameter, inner diameter and length, namely D×d×L.

for example:

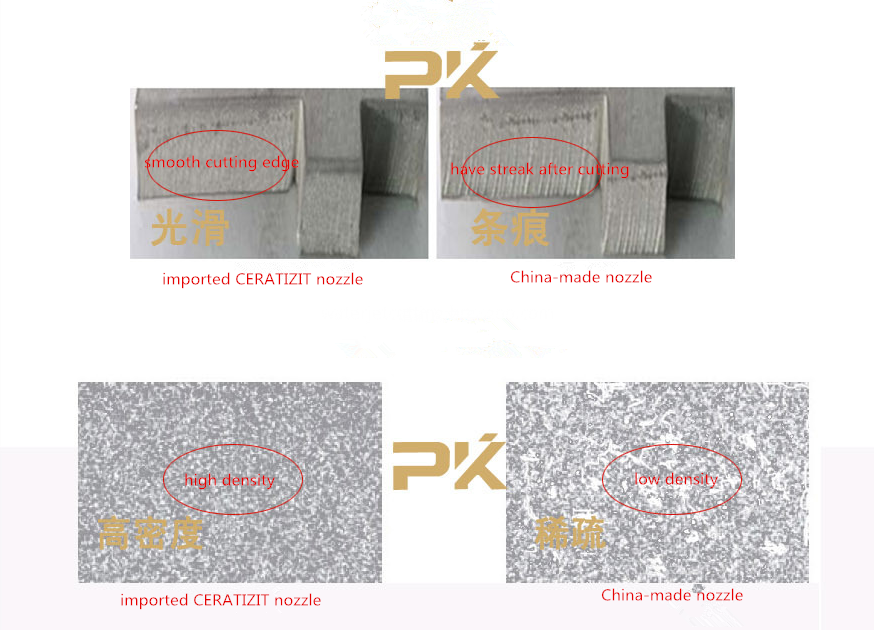

Material: The most ideal material for the current production of sand mixing tubes is tungsten steel. Tungsten steel, also known as cemented carbide or tungsten-titanium alloy, refers to a sintered composite material comprising at least one metal carbide composition. Tungsten carbide and cobalt are the main components of tungsten steel, accounting for 99% of all components. Tungsten steel has a series of excellent properties such as high hardness, wear resistance, strength and toughness, heat resistance and corrosion resistance. In particular, its high hardness and wear resistance are irreplaceable by other materials. The temperature of the sand pipe in Luxembourg's Serra is over 96HRA, reaching the leading level.

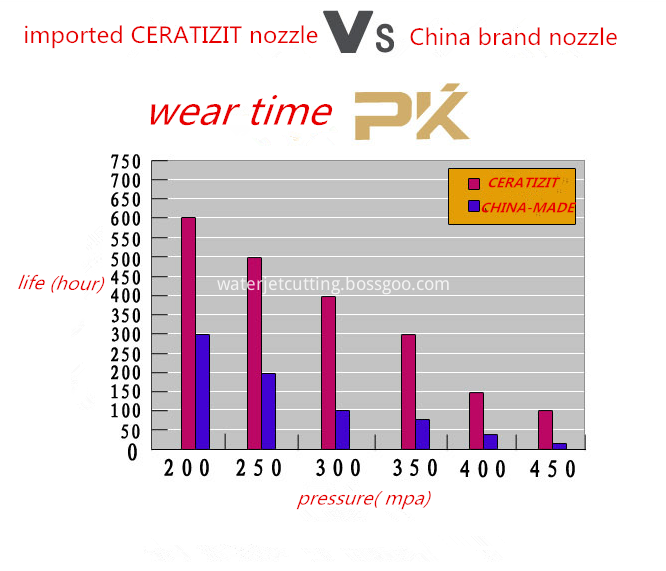

Lifespan: 150-300 hours refers to the general statistical time at a working pressure of 350 MPa. The service life of the sand mixing tube is affected by many factors, such as working pressure, water column, abrasive (pomegranate sand), cutter head structure design and some human factors.

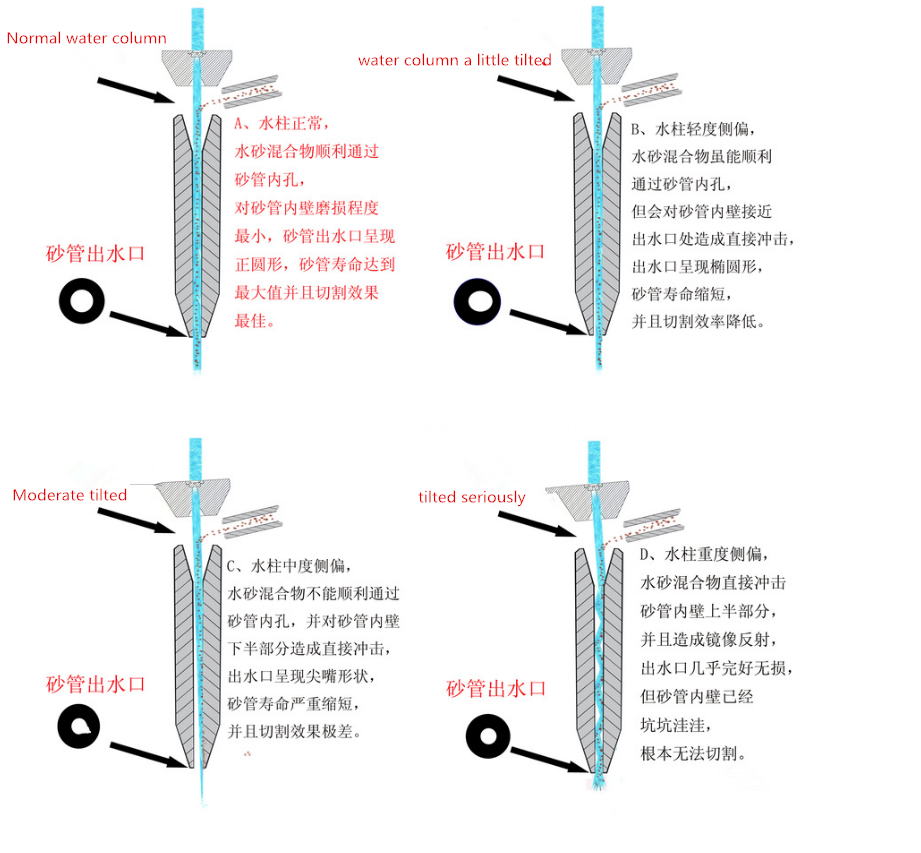

A : The water sand mixture smoothly passes through the inner hole of the sand pipe, and the inner wall of the sand pipe is the least worn, the water outlet of the sand pipe is round, the life of the sand pipe reaches the maximum and the cutting effect is the best.

B:Although the water sand mixture can smoothly pass through the inner hole of the sand pipe, it will directly impact the inner wall of the sand pipe close to the water outlet, and the water outlet is elliptical, the life of the sand pipe is shortened and the cutting efficiency is lowered.

C : The water sand mixture can not smoothly pass through the inner hole of the sand pipe, and directly impacts the lower half of the inner wall of the sand pipe. The water outlet has a pointed shape, the life of the sand pipe is seriously shortened, and the cutting effect is extremely poor.

D : The water sand mixture directly impacts the upper part of the inner wall of the sand tube, and causes mirror reflection. The water outlet is almost intact, but the inner wall of the sand tube has been pitted and cannot be cut at all.

WHY YOU CHOOSE THIS NOZZLE?

1. HIGHER PRECISION

2. HIGHER USING TIME

3. MORE STABLE CUTTING

4. HARDNESS IS BETWEEN 26.5-28.5KG/MM

5. USING COST PER HOUR IS MUCH LOWER.

6. BETTER CUTTING RESULT

Sand mixing tube installation steps:

1. Make sure that the orifice nozzle seat and sand mixing tube jacket surface are clean and free of dust.

2. Install the orifice first to test if the water column is straight line, then install the sand mixing tube.

3. Test with low pressure and no sand until the water column is in a straight line without scattering. After concentric, added abrasive sand and begin normal cutting.

4. After using the sand mixing tube for 10-20 hours, rotate the sand mixing tube by 120 degrees.

Factors affecting the life of the waterjet mixing tube:

1. Whether the inner diameter of the orifice and the inner diameter of the sand mixing pipe are 1:3; for example, the inner diameter of the sand mixing pipe is 1.0mm, and the inner diameter of the ruby orifice should be 0.33mm. This ratio has been tested extensively, and the cutting is the most powerful. The wall wear to waterjet nozzle is minimal.

2. The particle size and quality of the sand, too coarse and contaminated sand will accelerate the wear of the waterjet nozzle;

3. Dirty, hard, and not well-filtered water can easily destroy the waterjet orifice when it is under high pressure, and the injected water will scatter, which will quickly damage the inner wall of the water jet cutting machine nozzle.

4. The main influencing factor is the concentricity of the waterjet orifice and the waterjet nozzle. Even the extremely small deviation of the concentricity will cause the sand and water to deflect, directly impacting one side of the inner wall of the waterjet nozzle, thus rapidly wearing the waterjet nozzle.

What nozzle size we have?

Product Categories : Water Jet Cutting Machine > Waterjet Spare Parts