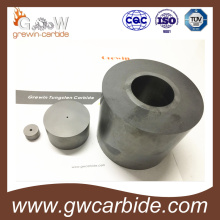

Tungsten Carbide Cold Forging Die for Moulds

Basic Info

Model No.: all sizes

Product Description

Model NO.: all sizes Casting Form Material: Metal Casting Form Usage Count: Semi-permanent Surface Roughness: Ra0.1 Machining Tolerance: +/-0.01mm Certification: SGS, ISO 9001:2000, ISO 9001:2008 Trademark: GW Specification: 33x23x19cm HS Code: 8207209000 Casting Method: Sand Casting Casting Metal: Cast Iron Surface Treatment: Polishing Coating: Water Standard: AISI Grade: Yg16c Ygh40 Yg2c Ylh90 Transport Package: Standard Box Origin: Zhuzhou Product Description

100% raw material Tungsten Carbide Cold Forging Dies for moulds

1 / CHARACTERISTICS

1.High wear resistance

2. Excellent in polishing.

3. Adhesion to metal is small.

4. The friction coefficient and energy consumption is small.

5. High thermal conductivity.

6. Good corrosion resistance.

2 / GRADE AND SPECIFICATION OF COLD HEADING DIES

3/ PRODUCTION PROCESS

Mixture(WC+CO+alcohol)→wet grinding→ drying→grinding again→suppression(Oil press,Automatic hydraulic press)→QC for blank→rubber extrusion→Wc+Co→sintering(HIP )→tungsten carbide blank→Fine grinding→QC→packing.

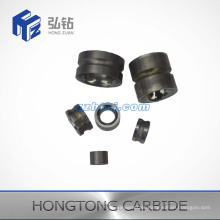

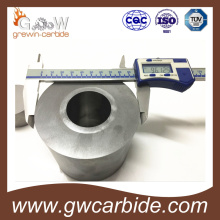

4/ PRODUCT SHOW Contact us if you need more details on Cold Forging Dies. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Dies、Carbide Tools. If these products fail to match your need, please contact us and we would like to provide relevant information.

100% raw material Tungsten Carbide Cold Forging Dies for moulds

1 / CHARACTERISTICS

1.High wear resistance

2. Excellent in polishing.

3. Adhesion to metal is small.

4. The friction coefficient and energy consumption is small.

5. High thermal conductivity.

6. Good corrosion resistance.

2 / GRADE AND SPECIFICATION OF COLD HEADING DIES

| Grade | Density(g/cm3) | Flexural strength (N/mm2) | HRA | Application |

| YG16C | 13.7-14.1 | ≥2400 | ≥84.0 | General impact resistance with forging die, red playing mode, etc. |

| YGH40 | 13.5-13.9 | ≥2450 | ≥83.0 | Mainly used for the production of red die. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | For those mold impact is not big, such as stamping parts, watches battery shells, small nuts, etc. |

| YG2C | 13.4-14.8 | ≥2480 | ≥82.5 | Applicable standard parts, bearings and other production of cold heading, cold punch, and cold mold made. |

| YLH40.5 | 13.3-13.6 | ≥2540 | ≥82.0 | Generally used for the production of stainless steel screws mold and screw mold . |

| YLH90 | 13.2-13.5 | ≥2580 | ≥81.5 | Used to make impact resistance forging die. |

| YLH100 | 13.0-13.4 | ≥2650 | ≥81.0 | Main production of various kinds of punching die, punch and other wear-resistant parts, high strength and impact resistance performance. |

Mixture(WC+CO+alcohol)→wet grinding→ drying→grinding again→suppression(Oil press,Automatic hydraulic press)→QC for blank→rubber extrusion→Wc+Co→sintering(HIP )→tungsten carbide blank→Fine grinding→QC→packing.

4/ PRODUCT SHOW Contact us if you need more details on Cold Forging Dies. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Dies、Carbide Tools. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Tungsten Carbide Cold Forging Dies

Premium Related Products

Other Products

Hot Products

Tungsten Carbide Button Bits with Various SizesCarbide Round Cutting Disc Ys2t Yl10.2 Yg15XHigh Wear Risistance Tungsten Carbide Nozzles SGSTungsten Carbide Wood Cutting Saw Tips Yg6 K10Tungsten Carbide Pins Used for Car TyreHigh Quality Solid Carbide Rotary BurrsHigh Quality Tungsten Carbide Ring for ToolsTungsten Carbide Tips for Drilling ToolTungsten Carbide Ball Hot SaleTungsten Carbide Stamping Dies Punching Dies Yg20c Yg25cFinished Cemented Carbide Wire Drawing Dies with Steel CaseCemented Carbide Rock Drilling Bits Mining Button Yk05Tungsten Carbide Strip Grade K10/K20/K30Tungsten Carbide Brazed Inserts K10 P10 M10HRC 45 50 60 2 Flutes Ball Nose Carbide End MillHigh Quality Tungsten Carbide Rods YL10.2 h6