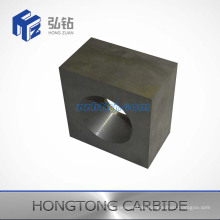

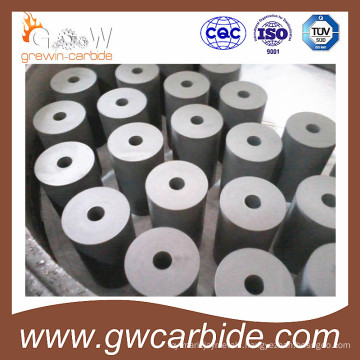

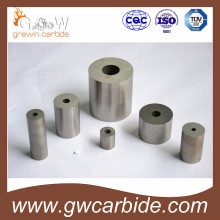

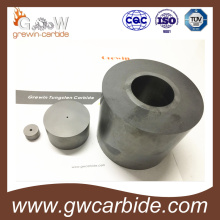

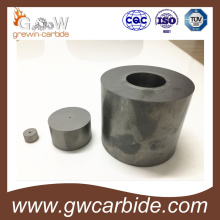

Tungsten Carbide Cold Forging Dies Sinter Hip

Basic Info

Model No.: all sizes

Product Description

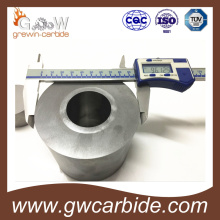

Model NO.: all sizes Material: Carbide Technics: Forming Die Manufacturing Technology: Computer Technology Mold Cavity Technology: EDM Milling Parts Detection Method: Geometric Detection Tolerance: Rough Grind on O.D, Grind Top and Bottom Surface Materials: 100% Raw Material Tungsten Carbide Transport Package: Standard Export Carton Origin: Zhuzhou, Hunan Application: Household Appliances, Hardware, Commodity Processing Method: Punching and Shearing Mould Process Combination: Progressive Die Driving Motor Type: Permanent Magnet Milling Speed: High Speed Grades: Yg20c, Yg25c, Kg7, Va80, Va90, Wf40 Delivery Time: 3 ~ 15 Days Trademark: G&W Specification: 33x23x19cm HS Code: 8207209000 Carbide cold forging dies

1. Our advantage

1 100% raw material, HIP-Sintered

2 No porosity, no crack

3 Good wear resistance, long working life

4 High bending strength, good impact resistance

5 Finish grinding, concentricity of O.D and I.D

6 Good corrosion resistance

7 Big production capacity, delivery time within 3 ~ 15 days

8 Strong technical support, good after sale service

2. Grades

Other grades of tungsten Carbide Forging Dies can be offered according to customers' requirement

3. Production process

Mixture(WC+CO+alcohol)→wet grinding→ drying→grinding again→suppression(Oil press,Automatic hydraulic press)→QC for blank→rubber extrusion→Wc+Co→sintering(HIP )→tungsten carbide blank→Fine grinding→QC→packing.

Contact us if you need more details on Tungsten Carbide Cold Forging Dies. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tungsten Carbide Pellet、Carbide Forging Dies. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. Our advantage

1 100% raw material, HIP-Sintered

2 No porosity, no crack

3 Good wear resistance, long working life

4 High bending strength, good impact resistance

5 Finish grinding, concentricity of O.D and I.D

6 Good corrosion resistance

7 Big production capacity, delivery time within 3 ~ 15 days

8 Strong technical support, good after sale service

2. Grades

| GRADE | DENSITY (g/cm3) | TRS (N/mm2) | HARDNESS (HRA) | Application recommended |

| YG11 | 14.4 | 2600 | 88.5 | Forming or stamping dies for metal powders and nonmetal powders. |

| YG15 | 14.0 | 2800 | 87.5 | For fabricating drawing dies of steel tubes and rods under High compressibility ratio; punching,stamping,forging tools under large stress. |

| YG20 | 13.5 | 3200 | 85.5 | For fabricating of stamping dies for watch parts, spring plates of musical instruments, battery jars, small sized steel balls, screws, screw caps. |

| YG16C | 13.9 | 2900 | 85.5 | Impact resistance forging dies. |

| G18C | 13.7 | 3100 | 84.5 | Impact resistance forging dies, hot-press forging dies and rollers. |

| YG20C | 13.5 | 3300 | 83.5 | Dies for wear resistant or impact resistant application. |

| YG22C | 13.3 | 3500 | 83.0 | Nut forming dies and high impact resistance forging dies |

| YG25C | 13.1 | 3600 | 82.5 | Stainless bolt header dies and rollers. |

3. Production process

Mixture(WC+CO+alcohol)→wet grinding→ drying→grinding again→suppression(Oil press,Automatic hydraulic press)→QC for blank→rubber extrusion→Wc+Co→sintering(HIP )→tungsten carbide blank→Fine grinding→QC→packing.

Contact us if you need more details on Tungsten Carbide Cold Forging Dies. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tungsten Carbide Pellet、Carbide Forging Dies. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Tungsten Carbide Cold Forging Dies

Premium Related Products

Other Products

Hot Products

Tungsten Carbide Button Bits with Various SizesCarbide Round Cutting Disc Ys2t Yl10.2 Yg15XHigh Wear Risistance Tungsten Carbide Nozzles SGSTungsten Carbide Wood Cutting Saw Tips Yg6 K10Tungsten Carbide Pins Used for Car TyreHigh Quality Solid Carbide Rotary BurrsHigh Quality Tungsten Carbide Ring for ToolsTungsten Carbide Tips for Drilling ToolTungsten Carbide Ball Hot SaleTungsten Carbide Stamping Dies Punching Dies Yg20c Yg25cFinished Cemented Carbide Wire Drawing Dies with Steel CaseCemented Carbide Rock Drilling Bits Mining Button Yk05Tungsten Carbide Strip Grade K10/K20/K30Tungsten Carbide Brazed Inserts K10 P10 M10HRC 45 50 60 2 Flutes Ball Nose Carbide End MillHigh Quality Tungsten Carbide Rods YL10.2 h6